The dream of solar cell and PV module manufacturing outside of Asia has become increasingly distant. A combination of falling PV module prices and China’s PV module manufacturers allegedly sitting on up to two months’ worth of stock is adding to the maelstrom. Plans for GW-scale PV cell and module production facilities in the US and Europe have been delayed or outright scrapped, and to make it worse, Western markets are accumulating inventories stocked with products purchased for double the current end-of-the-year market prices.

This solar storm is wreaking havoc on the industry, leading to cracked glass in modules and an even more fractured supply chain. In times like these, it could be best to reflect on words uttered by Albert Einstein, who once reportedly said, “Make things as simple as possible, but not simpler”. His argument, that an idea should be made as coherent as possible without being stripped of its meaning, could be applied to solar PV in this current market. Make PV modules as cheap as possible, but not cheaper. Because with anything in life, there is a final price.

How did PV modules become so cheap?

Solar has become the most affordable and fastest-growing energy generation technology. It has surpassed all other renewable and conventional electricity generation technologies year-on-year since 2015. Part of its popularity is rooted in price, with each company being extremely price competitive due to a range of market factors and product improvements. This includes lower kerf losses, better cell packing in modules, less silver, thinner glass, thinner frames, larger modules, cheaper electricity and most importantly, companies flooding the market with products. Consumers buying cheaper decentralized solar rooftop PV systems or utility-scale installation technologies have reaped the rewards. But as time wears on, particularly for large-scale operators, fissures have emerged.

The price of cheap PV modules

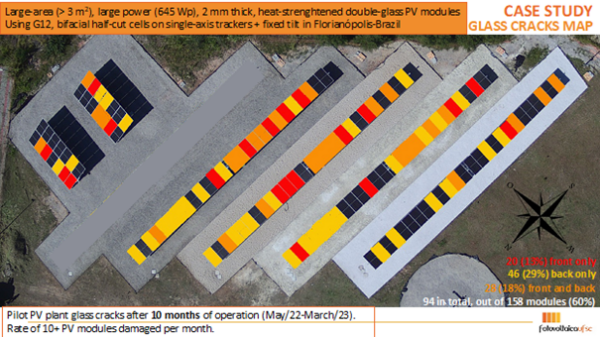

Over the span of a decade, PV modules have almost doubled in size with thinner frames, thinner glass and shorter mounting rails. Half-cut cell modules now normally have three holes in the rear glass allowing them to bear a significant weight of the PV load. The shift occurred in 2017 when 2-millimeter-thick hardened (not fully-tempered) glass became cheaper than the PV module gold standard of 3.2-millimeter fully-tempered glass. Around the same time, utility-scale PV power plants began to use mainly bifacial, double-glass.

Nearly all large-scale PV plants today use bifacial, double-glass modules with 2-millimeter-thick glass at the front and rear. But utility-scale solar power plants installed in recent years, which rely on 2-millimeter double-glass PV modules, are reporting up to 10% breakage rates.

The cracks observed are causing warranty claims and contractual disputes costing money, time and integrity. This means that cheap PV is not only leading to worse outcomes for the energy consumer but is also fracturing the industry, impacting PV module and PV tracker suppliers, engineering, product and construction companies, and PV plant owners. This is the case for making PV modules as cheap as possible, but not cheaper.

Author: Prof. Ricardo Rüther (UFSC).

ISES, the International Solar Energy Society is a UN-accredited membership NGO founded in 1954 working towards a world with 100% renewable energy for all, used efficiently and wisely.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.